Project Initiation

Customer demand mining from phenomenon to essence

As one of the leading suppliers of quick-change plates in the automotive welding field, Qiaotian Intelligence's core customer base covers vehicle manufacturers and large-scale parts suppliers.

In close collaboration with these clients, the Bridgefield Product Manager team noticed a clear trend of feedback:

The explosive growth of new energy vehicles, along with the shortening of model iteration cycles, the trend of lightweight vehicle bodies, and personalized customization options, has driven the continuous increase and diversification of orders for upstream injection-molded vehicle body component suppliers.

"During that period, when communicating with several long-term upstream and downstream automotive suppliers, they would always mention the pressure to improve efficiency on the production side," said General Manager Liu Xiaoping. "Specific issues include the rapid growth of orders for plastic parts related to new models, but the mold switching of injection molding machines cannot keep up with the pace, and equipment often wastes a lot of time due to mold changes and malfunctions."

This caught the attention of General Manager Liu Xiaoping: Bridgefield's quick-change disk technology has become a key equipment for enhancing the flexibility of production lines by enabling rapid switching of welding fixtures, but why is the key process "injection molding" stuck at the "rapid switching" stage?

To verify and delve deeper into this pain point, the Hashida team immediately launched a targeted survey of more than a dozen large-scale injection molding manufacturers that supply components to different new energy vehicle manufacturers.

The research methods include on-site observation of the standard mold change process, as well as in-depth interviews with workshop supervisors, equipment engineers, and mold change technicians.

Finally, the truth hidden behind the bottleneck in productivity improvement was clearly identified: The technological iteration of the mold change method is the core to solving the efficiency bottleneck.

For example, a plastic parts enterprise requires the collaboration of 4 workers during mold change, involving the disassembly, handling, reinstallation, and repeated calibration and positioning of up to hundreds of bolts. Completing a mold change takes an average of 1.5 to 2 hours.

The supervisor of the workshop said, "The frequency of mold changeovers for the new project has increased by approximately 60-70% compared to two years ago, but the time for each mold changeover has hardly been reduced, and the bottleneck in order delivery has become the norm."

The Bridgefield Team concludes that against the backdrop of the explosive growth of new energy vehicles and the rapid iteration of vehicle models, the industry has a fundamental need for technological iteration of efficient, rapid, and flexible mold change solutions, and even many customers are not yet aware that the essence behind the phenomenon is the iteration of mold change methods.

Based on this, at the beginning of 2023, Qiaotian Intelligence established a new product team led by a doctoral graduate from Jiaotong University, quickly entering the magnetic mold change product line, thus initiating the trial of Qiaotian Intelligence's second growth curve.

Test the waters

The perfect delivery of new products requires further improvement in Operational Efficiency

Qiaotian Intelligence adopted a prudent and steady market strategy during the early stage of the magnetic mold change product's market launch:

First, initiate small-batch order cooperation with component suppliers in the automotive industry chain, rather than directly promoting to vehicle manufacturers.

The core logic of this strategy lies in:

The application scenario of high-frequency mold change by component suppliers and their complex mold adaptation environment serve as the best touchstone for verifying the reliability and adaptability of new product systems.

During the initial cooperation and on-site verification process, the Qiaotian Team systematically identified the real pain points in the high-frequency mold change environment, bottlenecks in the operation process, and the complexity of mold management through close collaboration with frontline operators, technical engineers, and management personnel.

This process not only verified the reliability and practicality of the core functions of Qiaotian's magnetic mold change products, but also enabled the Qiaotian team to recognize the adaptability challenges of new products in the delivery process and resources.

"The technical advantages of the laboratory must be transformed into production line delivery capabilities through an efficient operating system; otherwise, they are just expensive handicrafts." General Manager Liu Xiaoping proposed. The Qiaotian Product Manager team quickly took action and identified the core points of internal process optimization:

01 Market Positioning and Customer Segmentation Recalibration:

Based on the industry knowledge accumulated from the initial pilot, reevaluate the target market of magnetic mold change products, and clarify the core value demands of different customer groups()and the differences in customization levels.

For example, compared to large home appliance customers, the mold change requirements of automotive OEMs not only include rapid mold switching but also involve the automatic docking of energy pipelines. Therefore, for this type of customer, promoting the combination of magnetic plates with energy docking is the optimal product solution strategy.

02 Build a Differentiated Demand Response Mechanism:

Based on different customer segments, establish special project teams to quickly match customer needs.

For example, for customers in the metal manufacturing industry, large-tonnage injection molding machines, large molds, and a large number of orders with small batches and multiple varieties that require frequent switching mean that efficiency optimization should be the goal. At the beginning of the project, the compatibility between injection molding machines and magnetic mold change products should be well evaluated to ensure the timeliness of planned delivery.

For medical apparatus customers, with relatively small mold tonnage and low switching frequency, it is necessary to aim at improving product positioning accuracy, ensure standardization from process manufacturing to quality inspection, and meet the customers' requirements for green production.

Through targeted restructuring and efficiency improvement of internal processes, the optimization of the operational system has effectively accelerated the market transformation of technological value at Qiaotian. Qiaotian's new magnetic mold change product has achieved market breakthroughs:

Successfully joined hands with Midea Group to implement the first automatic mold change system within the Midea system at the Jingzhou Washing Machine Factory.

Feedback

The first key milestone

Midea's Jingzhou Washing Machine Project was successfully delivered

Before collaborating with Qiaotian Intelligence, the rapid mold change project at Midea Washing Machine Jingzhou Factory had already undergone two rounds of internal innovation:

Driven by the pursuit of production efficiency and the high standard requirements for continuous optimization, in 2023, the Midea team first shortened the mold change time by preheating the mold in advance, and having multiple people collaborate to complete steps such as transporting the mold off the machine, drying it, and warehousing it.

In 2024, the Midea team will replace the manual mold clamping method with hydraulic mold clamping, upgrade the manual mold installation positioning to a quick-change tooling for the locating ring, upgrade the manual mold clamping to hydraulic mold clamping with a mold clamp, etc., to further improve mold change efficiency.

In 2025, based on the demand for production capacity targets, Midea Washing Machine Jingzhou Factory selected Qiaotian Intelligence as a partner to jointly initiate the third iteration of mold change for this project.

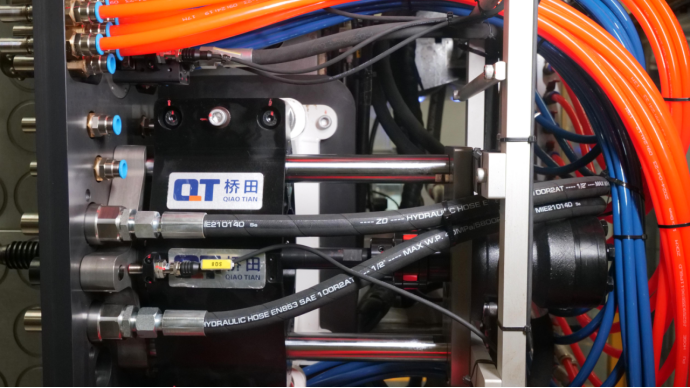

First, the Hashida team uses energy quick-connect modules for mold separation and connection during the mold installation and removal process, replacing the original manual plugging and unplugging of connectors, reducing the connector plugging and unplugging time during mold change by over 95%.

Meanwhile, it saves the cost that would otherwise cause the annual maintenance cost of equipment to increase by 5%-8% due to incorrect insertion, missed insertion, misinsertion, and insufficient insertion and extraction force during manual plugging and unplugging.

After integration into the energy quick-connect panel, the total mold change time is reduced by 630 hours per year, saving Midea 66% in costs.

Secondly, the Hashida team standardized the specifications of the dynamic/static mold docking plates, eliminating the installation differences on the mold side and reducing the task that originally required the collaboration of 3 people to be independently completed by 1 person. Then, they replaced the hydraulic clamping device with a magnetic template for mold clamping, enabling molds of different specifications to be quickly clamped within seconds.

After being put into production, the mold change time for Midea's first qualified product was shortened to 27 minutes for one person, and production efficiency increased by 32%.

As the first magnetic plate + plug-in board project of Qiaotian applied to large-scale equipment over 1,000 tons, Midea Group's high standards for technology implementation and project delivery have enabled Qiaotian Intelligence to gain valuable experience in project operation of new products in large and complex scenarios.

Directly drive the faster improvement and optimization of the internal processes of Qiaotian Smart's new products, laying a solid foundation for the subsequent large-scale production and delivery of projects with higher standards.

Iteration

Key Points from Small Batch to Scalability

lies in continuously improving the customer experience

Today, Qiaotian Magnetic Die Change products have entered a critical stage of large-scale development. General Manager Liu Xiaoping proposed:"Your competitor is not your peer, but the ever-changing market demand."

To this end, the Bridgefield Product Manager team has identified the core path for future in-depth iteration, focusing on the following dimensions:

01 Product Function Iteration and Upgrade:

Drive internal cost reduction and efficiency improvement, continuously invest more resources in the R&D and upgrade of core technologies, such as increasing the operating temperature of magnetic plates and enhancing the average adsorption force of magnetic units in special molds, enabling customers to obtain higher-quality products at the same price.

02 Shorten project delivery cycle:

Strengthen the quality management of internal suppliers and process training for production line personnel, and at the same time, adopt the form of project manager follow-up during the starting phase to ensure that project processes and milestones are controllable, etc.

03 Improve the quality of after-sales services:

After the project is completed, the special project team conducts regular follow-up visits to understand the situation, while establishing a multi-channel customer feedback mechanism and strengthening regular training for after-sales personnel to ensure that customer needs are responded to promptly.

At the level of new product development, the core logic of Qiaotian Intelligence revolves around customer needs as the first principle, rather than habitually developing products from its own perspective as a customer. Only in this way can it accurately grasp the second growth curve of the enterprise and continuously enhance the customer value of this curve.

2025-09-01

2025-09-01

9

9