2025-09-01

2025-09-01

5

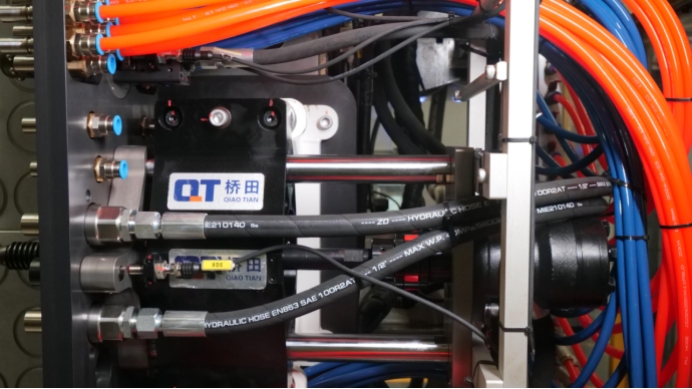

5By the first half of 2025, Qiaotian Intelligent once again delivered its first ‘mid-term’ results for the year with growth exceeding 40%. Equally exciting alongside order growth is the rapid breakthrough and grand debut of Qiaotian's second growth curve: magnetic tooling changeover products.

Project Initiation

Uncovering Customer Needs: From Phenomenon to Essence

As a leading supplier of quick-change discs in automotive welding, Qiaotian Intelligent serves a core clientele comprising OEMs and major component suppliers.

Through close collaboration with these partners, Qiaotian's product management team identified a clear trend:

The explosive growth of new energy vehicles has shortened model iteration cycles while driving trends towards bodyweight reduction and customisable options. This has fuelled sustained and diversified order growth for upstream injection-moulded body component suppliers.

‘During that period, discussions with several long-term automotive upstream and downstream suppliers consistently highlighted pressures to enhance production efficiency,’ remarked General Manager Liu Xiaoping. ‘Specific challenges included rapid growth in orders for plastic components related to new models, yet injection moulding machines struggled to keep pace with mould changeovers. Equipment frequently wasted significant time due to mould changes and malfunctions.’

This caught General Manager Liu Xiaoping's attention: while Kyoda's quick-change disc technology had become a key piece of equipment for enhancing production line flexibility by enabling rapid switching of welding fixtures, the critical process of ‘injection moulding’ was stalled at the ‘rapid changeover’ stage?

To validate and delve deeper into this pain point, the Kyoda team immediately conducted targeted research with over ten large injection moulding component manufacturers supplying various new energy vehicle manufacturers.

The methodology included on-site observation of standard mould-changing procedures and in-depth interviews with workshop supervisors, equipment engineers, and mould-changing technicians.

Ultimately, the truth behind the production efficiency bottleneck was clearly identified: technological iteration in mould-changing methods is central to resolving efficiency constraints.

For instance, one plastics component manufacturer required four workers to collaborate during a die change, involving the removal, handling, reassembly, and repeated calibration of up to a hundred bolts. Completing a single change took an average of 1.5 to 2 hours.

The workshop supervisor remarked: ‘Die change frequency for new projects has increased by approximately 60-70% compared to two years ago, yet the time per change has barely decreased. Order delivery bottlenecks have become the norm.’

The Qiaotian team concluded that against the backdrop of explosive growth in new energy vehicles and rapid model iteration, the industry fundamentally requires technological evolution for efficient, rapid, and flexible mould change solutions. Many clients remain unaware that the underlying cause of these challenges lies in outdated mould change methodologies.

Consequently, in early 2023, Qiaotian Intelligent established a new product team led by a PhD from Jiaotong University, rapidly entering the magnetic mould change product line. This marked the beginning of Qiaotian Intelligent's second growth curve trial.

Testing the Waters

Perfect product delivery demands enhanced operational efficiency

During the initial launch phase of its magnetic mould-changing products, Qiaotian Intelligent adopted a prudent and steady market strategy:

First, it engaged in small-batch order collaborations with component suppliers within the automotive supply chain, rather than directly promoting to original equipment manufacturers (OEMs).

The core rationale behind this strategy was:

The high-frequency mould-changing scenarios and complex mould adaptation environments encountered by component suppliers provided the ultimate litmus test for validating the reliability and adaptability of the new product system.

During initial collaborations and on-site validation, the Qiaotian team worked closely with frontline operators, technical engineers, and managers to systematically identify genuine pain points, workflow bottlenecks, and the complexities of mould management within high-frequency changeover environments.

This process not only validated the reliability and practicality of Qiaotian's core magnetic changeover functionality but also revealed challenges in the product's delivery processes and resource adaptation.

‘Laboratory technological advantages must be translated into production line delivery capabilities through efficient operational systems; otherwise, they remain merely costly artefacts,’ emphasised General Manager Liu Xiaoping. Qiaotian's product management team swiftly identified core areas for internal process optimisation:

01 Recalibration of Market Positioning and Customer Segmentation:

Building upon industry insights gained from initial trials, the target market for magnetic die-changing products was reassessed. This clarified the core value propositions and varying degrees of customisation required by distinct customer segments.

For instance, compared to major appliance clients, automotive OEMs require not only rapid mould changes but also automated energy line connection. Thus, promoting magnetic plates combined with energy line connectors represents the optimal product strategy for such customers.

02 Establishing a Differentiated Demand Response Mechanism:

Specialised teams were formed to rapidly match customer requirements based on segmentation.

Before collaborating with Qiaotian Intelligence, the rapid mold change project at Midea Washing Machine Jingzhou Factory had already undergone two rounds of internal innovation: